Welcome to Gemini Marine Canvas

Not your average canvas shop

At Gemini Marine Canvas we couple award-winning design with high-quality materials to offer the best custom canvas and upholstery for your boat, home and business. Our crew has decades of experience creating beautiful custom canvas and upholstery for hundreds of boats, many of which belong to repeat customers.

We’ll help you choose from hundreds of fabrics, foams, fasteners and fixtures, with as much or as little guidance as you’d like from our skilled and friendly staff. We only use the best for a polished finish that will last for years, including:

- Fabrics and vinyls from Sunbrella (both tops and covers and marine upholstery), Serge Ferrari (also for covers and upholstery), Stamoid and more

- Window clear from Strataglass, O’Sea and Tuffak Makrolon

- UV-stable Tenara thread (from the people who make Gore-tex fabrics)

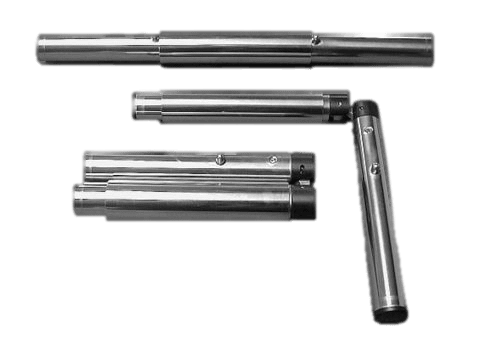

- Our own patented 316 marine-grade stainless steel hardware

So sail or power, indoors or out, big new builds and small repairs, our quality speaks for itself – and we’re here all year round.

“This is just a quick note giving you feedback on the new canvas enclose on Annisquam III. It works great!! It allows us room to move around when totally enclosed, just what we were looking for. We just love it and thank you.”

– Another happy Gemini Marine Canvas customer

It’s not too soon

Order now for Autumn installation

While you’re waiting for Summer, let us worry about (next) Winter now.

Our residential canvas shelters your outdoor spaces from the worst Winter has to offer. Easy to install and remove, our tough cover panels keep wind and rain off your deck, windows or three-season room.

Perfect for seasonal residents or folks with rental properties, too. Learn more and contact us to discuss your project now to ensure we’ll have your panels built and installed before the snow flies.

2023 Award of Excellence

We did it again.

Our client wanted a full enclosure and matching sail cover with rigid solar panels that didn’t interfere with the boom (and vice versa – solar panels don’t like shade). It took a bit of doing, but John created a frame that gets the panels up and over the boom. It uses our own split side mounts to secure the panels, as well as a host of other hardware and fittings. The canvas looks great, the panels work great, the client is pleased as punch. Problem solved.

The build just won an Award of Excellence from the Advanced Textiles Association Marine Fabricator division. It will be featured in an upcoming edition of Marine Fabricator magazine. We couldn’t be happier.

Not all solar builds are this complex, but if we can do this, we can get solar on your boat, too. Give us a call.

Celebrating 25 years of excellence

John won his first design award from the Advanced Textiles Association (ATA)

in 1997 and was named a Master Fabric Craftsman by the

ATA’s Marine Fabricators Association in 1999.

Looking for Gemini Marine Products?

To discover and purchase our full line of unique 316 stainless hardware, please visit our sister site here.